How to Identify Different Types of Screws

Introduction

Screws come in a surprising variety of types, each suited for different purposes and materials. From flat-head wood screws to machine screws for metal work, understanding these types simplifies both home and professional projects. In this guide, we'll break down screw classifications by head, thread, and drive styles so you can confidently choose the right screw every time.

Head types

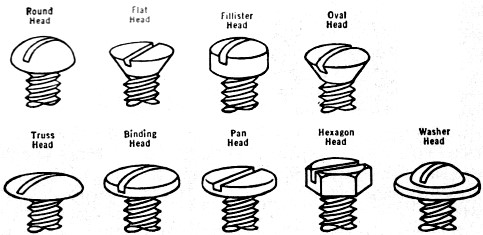

Screws are often categorized by the shape of their heads, each with specific applications that impact both functionality and appearance.

Types of Screw head shapes can be classified as:

- Flat Head: Ideal for countersinking, these screws are commonly used in woodworking projects where the head should sit flush with the surface for a smooth, finished look.

- Pan Head: With a rounded, low-profile top, pan heads are suited for surface mounting and often used in metal applications.

- Oval Head: Combining a slightly raised surface with a finished aesthetic, these are popular in cabinetry and applications where the screw head will be visible.

- Round Head: Known for its dome shape, this head style is often chosen for decorative applications or where a protruding head is acceptable, such as fixtures.

- Drywall Screws: Specifically designed to secure drywall to wooden or metal studs, these come with sharp or self-drilling points, making installation easy.

- Hex Washer Head: Known for durability, hex washer heads are commonly used in structural applications, providing a flush finish in construction projects.

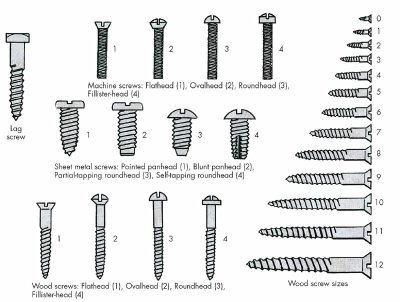

Thread Types: Matching the Screw to the Material

Each type of screw thread is designed for a specific purpose, often tied to the materials it is fastening.

- Sheet Metal Screws: Zinc-plated for corrosion resistance, these screws have sharp points ideal for fastening thin metal sheets.

- Drywall Screws: Available with sharp or self-drilling tips. Sharp tips work best with wooden studs, while self-drilling tips are suited for metal.

- Machine Screws: Made for use with nuts or threaded holes, machine screws are generally used in metal applications and available in various head shapes.

- Masonry Screws: Built to penetrate hard surfaces like brick and concrete, these screws are often used for mounting wall brackets, electrical boxes, and awning supports.

- Wood Screws: Their long length and durable grip make wood screws perfect for securely joining wood pieces in cabinetry and furniture-making.

- Self-Drilling Screws: Combining a drill bit and screw into one, these allow for direct metal-to-metal or metal-to-wood fastening without pre-drilling.

- Self-Tapping Screws: Featuring cross-cuts, these screws create their own threads as they drive into softer metals, making them ideal for aluminum.

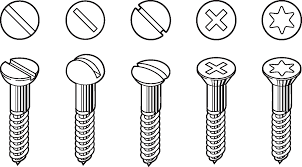

Drive Styles: Selecting the Best Fit for Your Tools and Project Needs

The drive style affects how you fasten the screw and the tool compatibility, which can influence project ease and security.

- Phillips Head: A common type with a cross-shaped slot, ideal for general-purpose applications and compatible with standard Phillips screwdrivers.

- Slotted Head: An older style with a single slot, best for low-torque applications.

- Hex Head: Often found in heavy-duty applications, this drive style offers increased torque control and is commonly used in bolts.

- Spanner Tamper Proof: Made from corrosion-resistant stainless steel, these screws provide additional security as they cannot be removed without a matching spanner screwdriver, making them ideal for high-security installations.

- Square Drive: Known for resisting cam-out (slipping), square drives are a reliable choice for woodworking applications.

Measuring Screw Length and Diameter: Ensuring a Perfect Fit

Correctly measuring screw length and diameter is crucial for compatibility with materials and achieving the desired depth.

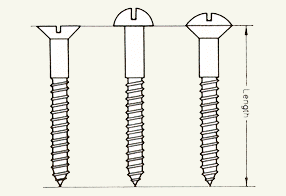

- Length Measurement: For screws where the head sits above the material (non-countersunk), measure from under the head to the screw's tip. For countersunk screws, measure from the flat part of the head to the tip.

- Diameter Measurement: To determine screw diameter, measure the shank width, or the distance across the screw's widest part, typically in millimeters or gauge sizes.

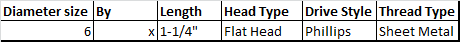

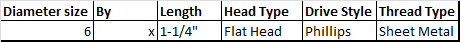

Nomenclature

When ordering different types of screws, the nomenclature is as follows:

CAT No. 6X114FHPSMS

CAT No. 8X34HWSMS