Spider Fittings for Glass: Everything You Need To Know

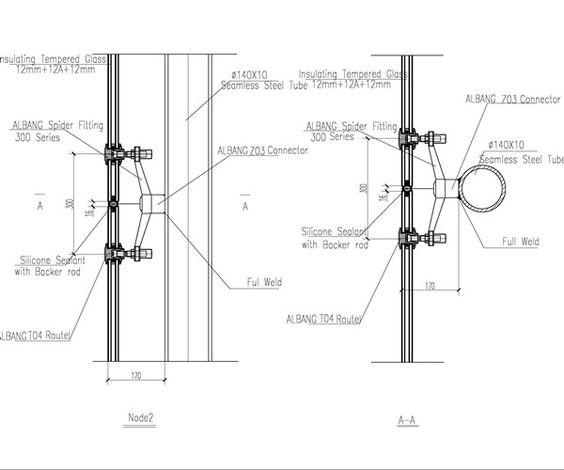

Spider fittings for glass are extensively used for all-glass facades in storefront applications. Named for their form factor, spider fittings can be attached to vertical columns, vertical 'I' beams, or vertical glass fins. To complement the look of glass, the fittings are finished in brushed or polished stainless steel. The steel has undergone structural testing to withstand panel weight and the region's wind load.

The spider fittings range from CR Laurence is available in fixed or swivel configurations in cap or flush styles. You can purchase heavy-duty, regular duty and mini spiders, which will be tested and certified to meet your specific installation needs. The technical sales department at CR Laurence provides assistance on the design and quotation process, and can even provide drawings stamped by a licensed engineer.

Systems and applications

A common use of spider fittings is for hand rail applications where they are attached to a vertical post. Heavy-duty spider fittings may be attached to the top of engineered beams to create a glass awning. Mini spider fittings can be modified for custom guard rail installations.

As far as systems are concerned, spider fittings are utilized for a column supported or glass fin supported system. In the former, vertical columns are designed to support the weight of the glass wall that is attached with spider fittings. In the latter, vertical heavy glass fins are positioned at 90 degrees to the glass wall, and the spider fittings attach to both the fin and the glass wall.

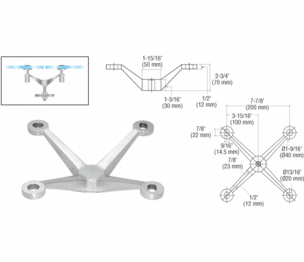

A look at some popular spider fittings

- PMH4BS brushed stainless steel 4-way arm heavy-duty post mount spider fitting to attach two inline glass panels to a structural center post.

- HSFEX14BS brushed stainless steel heavy-duty exterior swivel fastener.

- M16SET stainless steel replacement stud set for post mounted spiders.

Tips on using spider fittings for designing a façade

Decisions on which fittings are required for your project can only be accurately made by talking to the technical sales representatives. Technical drawings will need to be created, and all information must be provided to the structural engineer to evaluate the system for customer's and architect's approval. CRL's computer aided design (CAD) department creates shop drawings illustrating the facade design, type and number of spider fittings, as well as the glass attachment choice. This is an optional value-added service you can purchase at a reasonable cost when placing an order for your system.

The final step is to get a structural engineer's approval and supporting calculations on a stamped set of drawings. Detailed information in the first step of the process can help ensure quick and successful completion of the project.